|||

|||

It’s not every day that you catch a glimpse of a 33m-long Boeing 737 on an industrial estate, let alone climb into one. But that’s the sight which greets you as you walk towards the vast hangar housing the International Aviation Academy.

Located near Norwich International Airport, the facility is the only one in the world that provides a “live” aircraft – one that can still be flown – for training purposes. Inside its newly refurbished home, the 30-year old plane, which was leased from Royal Dutch Airlines KLM, is a constant reminder of the hands-on education this facility provides to the next generation of aviation professionals.

Designed by Hamson Barron Smith, the facility, which cost £8m to construct, is the first of its kind providing advanced training using 21st century technologies. According to the International Civil Aviation Organisation, the number of aviation engineers and professionals that need to be trained worldwide has been falling short by around 18,000 places every year, and the academy was established to help address this chronic skills shortage in the UK.

The facility offers courses in aviation engineering, but pilot training is expected to start in September. Aviation Skills Partnership, the body that led the project with KLM and which manages the programme, aims eventually to offer training in all key areas, including air traffic control, airport operations, cabin crew and operations.

Emma Darby, the partnership’s general manager for east and central, says: “We have already doubled the number of applicants starting in September compared to last year and it really helps that we have this lovely new building to show people what’s on offer.”

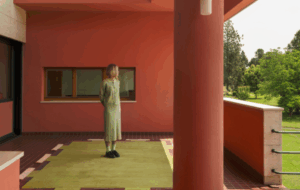

The new academy is housed in a 90m x 45m former “Type C” standard Ministry of Defence hangar that was built in 1938. During the Second World War, it was used by the Royal Air Force to maintain and store aircraft. After the war, the hangar was converted into light industrial use. By 2014, when the architect was appointed, it was being used to assemble aluminium windows.

“It was in a very bad condition,” says Katarzyna Kwiatek, project architect at Hamson Barron Smith. “It was dark inside with no skylights, it had asbestos cladding, the roof was leaking, all the windows were broken and there was no lighting. It was not fit for purpose.”

Demolition was considered, says Kwiatek, but the structure was found to be robust, offering the possibility of reuse. The building is composed of a steel frame with the lower section of the steel columns encased in concrete. The columns are joined by bay-width 356mm thick and double reinforced concrete “blast walls”, up to a height of 6.24m. This very thick lower section was to help mitigate against explosions in the event of wartime bombing.

Given the structure’s good condition, it was cleaned and repainted, but the original saw-tooth roof was removed due to its poor state and a new flat roof added. The cladding was replaced with Kingspan’s insulated metal panel system and punctuated with a discreet main entrance and double-glazed windows to draw in daylight. These alterations have significantly improved thermal performance.

“It’s amazing how well it’s kept after all these years and the only thing we added was some additional structure to help support the new roof,” says Kwiatek. “We tried to re-use where possible and you can still see some of the existing structure and bits of concrete wall left in the classrooms and workshops. Our ambition was to retain the memory of the original building as much as possible.”

Hamson Barron Smith’s proposal thus became a recladding and retrofit exercise. The ingenious thing about the scheme is the simple but clever concept employed by the architects to break up the huge internal space. This divides the building’s interior into two halves, revealing and celebrating the reconditioned steel structure to stunning effect.

At one end of the building is a teaching zone containing 16 classrooms, while the more hands-on aviation emulation zone is located in the other half, with six workshops and two specialist classrooms. The architect arranged the classrooms and workshops around the perimeter, leaving the double-height central space clear for other uses. For example, within the teaching zone, the central atrium is occupied by a cafe and offices, enabling the rest of the space to be used for events. The classrooms – nine on the ground floor and seven on the first floor – encircle the atrium, with views into the space.

In the aviation emulation zone, the Boeing 737 dominates the central space and the academy is hopeful that the aircraft will soon be joined by a helicopter for student training. To accommodate the plane, the workshops are arranged over two levels.

“We inserted a double-height window in the emulation zone to allow passersby to see the aircraft from the carpark,” says Kwiatek. “The window allows the only natural light into the space because the aviation engineers said they needed artificial light for aircraft maintenance.”

The architects had to extend the building’s depth in the aviation emulation zone and design a triangular wedge to provide extra room for the tail of the plane which was longer and higher than the space available.

Along the middle of the building at ground level, two seminar rooms have been created, with glazing on both sides to enable views into the zones. These rooms can be separated by a folding wall or transformed into one large space, and there is potential for more rooms to be built above. Flexibility and scope for future expansion are key design features.

The classrooms – each with a name on the door relating to people in the aviation industry or sites significant to the local area – are of a generous 55sq m and comfortably seat 28 students. The classrooms, workshops and offices are naturally ventilated, but if windows can’t be opened due to noise disturbance, backup is provided via variable refrigerant volume flow units driven by air source heat pumps.

The rooms are let empty and clients add what they want – such as tables, desks and smart boards. “The clients are the different training providers,” Darby explains. “So far we have KLM Engineering, City College Norwich, Air Ambulance – and we’re working on getting other colleges and training providers in. We’ve had interest from British Airways and we could potentially have all the different airlines here.”

The soundproofing of both workshops and classrooms is excellent, a result no doubt of the additional acoustic panels. “We’ve had speaking events using speakers while students are studying and they have said they didn’t hear a thing, which is just as well because we need to run events – and it just proves that the building works well and is very flexible,” says Darby.

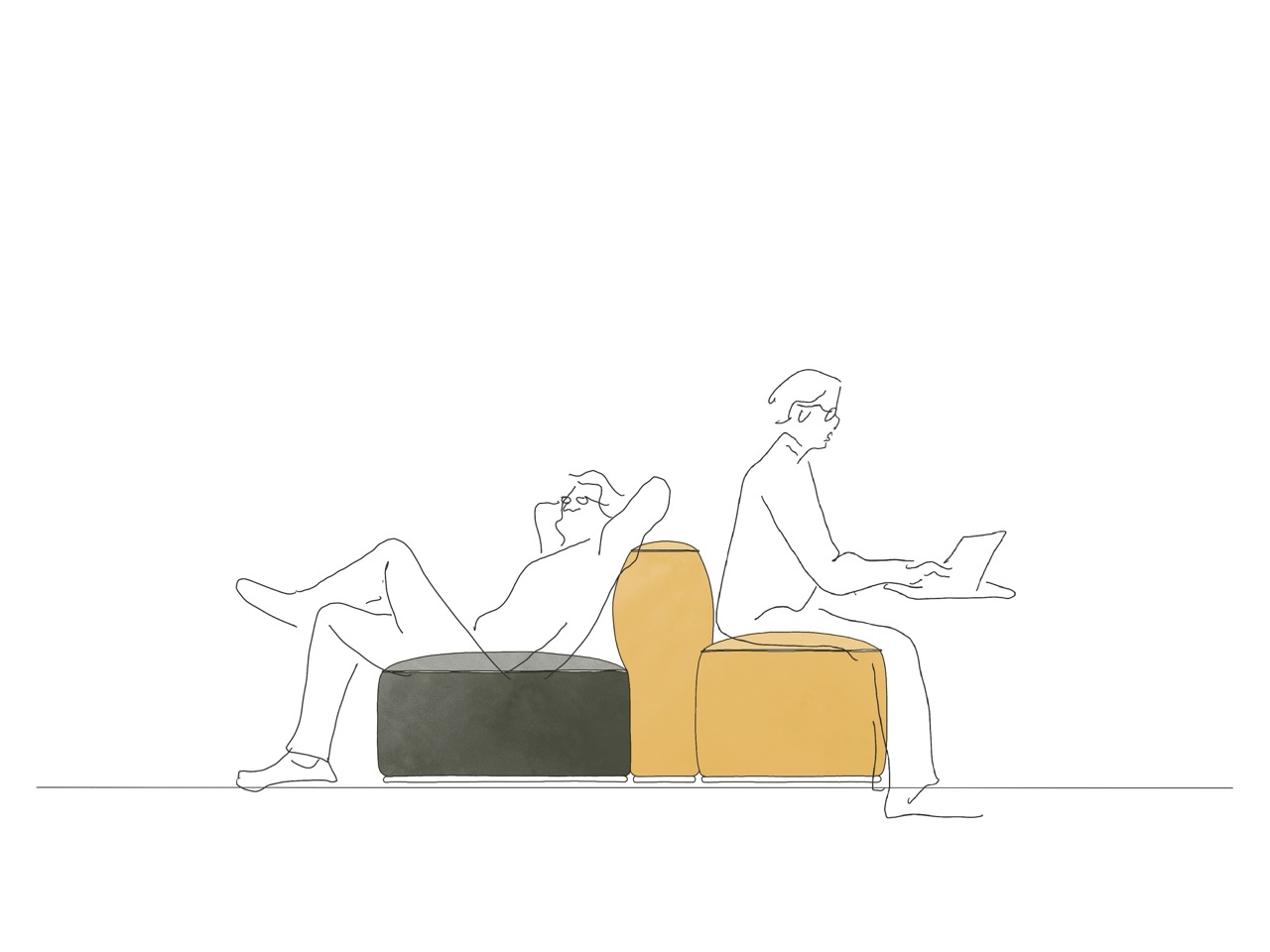

A fairly neutral palette and a light industrial appearance has been achieved by the grey carpet, furnishings, exposed services and steel roof structure. Flashes of bright yellow inject warmth. “We wanted a colour scheme that related to aviation rather than a specific user, because different tenants will be in this building so we wanted to keep it simple,” says Kwiatek.

Proposals for a hotel next to the academy, improved connections with Norwich Airport and potentially an aerospace academy, show that the area is changing. As Darby says: “By creating this lovely building and bringing a lot of people here, we like to think that we’re the catalyst for regenerating this industrial estate.”

A once-dilapidated hangar on a Norwich industrial estate has a new lease of life as an aviation academy – with its own plane