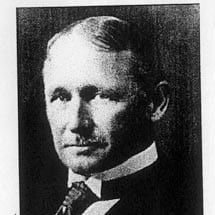

frederick taylor

frederick taylor

By Mark Eltringham

By Mark Eltringham

Taylorism, or “scientific management”, refers to American engineer Frederick W Taylor’s ideas to improve productivity in factories at the beginning of the 20th century. Starting from the observation that employees tended to work at the slowest rate they could without being punished – what he called “soldiering” – Taylor proposed what we would now recognise as the production line. Each production process is analysed and then systematised. Breaking these processes down into clearly defined tasks, each would be assigned to a worker performing this task and no other, with a defined production target. Production methods and tools would be standardised and workers would be selected on the basis that their character and education would suit the specific task.

Everybody likes a pantomime villain and for commentators on management and office design, they don’t come any more villainous than Frederick W Taylor. Not only do pictures portray him as wealthy, starched and bordering on smug, his ideas and the language in which they are couched seem totally out of step with the way we think now. So for anybody writing about enlightened contemporary management practices, it is no wonder that it’s almost customary to start with a rejection of Taylor and his theory of “scientific management”.

The gist of Taylorism, as laid out in his 1911 book The Principles of Scientific Management, is that work should be analysed “scientifically” to establish the most efficient way of doing it and the right person to carry it out, and that managers are there to make sure that it all goes to plan. His ideas were in large part a reaction to the conditions in American factories at the time, where the majority of workers were illiterate or semi-literate immigrants with a poor grasp of English. But, as far as the workers are concerned, what we now think of as Taylorism is best summed up as: “You’re not paid to think. Shut up and do your job.”

Taylor’s scientific management principles incorporated “time and motion studies” – the aim of reducing the number of motions in performing a task in order to increase productivity. And given that Taylorism essentially views workers as machines, the man has surely played a part in modern business aims of replacing workers with machines whenever possible.

Underlying Taylor’s ideas was a desire to do away with shirking. He had a life-long obsession with efficiency and believed that groups of people would develop peer structures that would encourage “natural laziness”, so he frequently discouraged workers from operating in teams of more than four. He also had very fixed ideas about what he meant by the right person for the job. “One of the first requirements for a man who is fit to handle pig iron,” he wrote, “is that he shall be so stupid and phlegmatic that he more nearly resembles in his mental make up the ox than any other type.”

It is not really surprising that this kind of language earned Taylor his demonised status in the modern world. Workers were no longer treated as individuals but as mere units, parts of a larger system. Taylorism didn’t go down particularly well at the time either, with workers in his steel works breaking machines in an attempt to show their disgust at his methods. It took three years of persistence (and fines) to bend them to his will. His ideas continue to strike a discordant, even outrageous, note when heard alongside contemporary corporate speak, with its talk of knowledge workers, motivation, empowerment, work-life balance, homeworking, portfolio careers and dress-down days.

Yet it is about time we reassessed both the man and his work. We reject Taylor’s ideas as outmoded, but companies will happily fork out thousands of pounds for their executives to go misty-eyed on courses exploring how the ancient musings of Chinese military strategist Sun Tzu are applicable to modern business. It doesn’t help that Taylor was pushing ideas learned in a steel factory and paper mill as opposed to a battlefield – we know how business people like to bathe in a martial glow. Sun Tzu can be rehabilitated even after saying about his soldiers, “if you are so nice to them that you cannot employ them, so kind to them that you cannot command them, so casual with them that you cannot establish order, they are like spoiled children, useless.”

As the late management consultant and commentator Peter Drucker pointed out, “scientific management was one of the great liberating, pioneering insights.” Workers were freed from the often arbitrary tyranny of management’s “rule-of-thumb” ideas about what was expected of them, and could now reasonably demand a share in the profits arising from improved productivity. Even the labour disputes that Taylorism provoked can be seen as part of a positive process whereby relations between workers and management were renegotiated to the benefit of the workers, who could point to the management’s own studies to prove their case.

Taylor advocated the use of suggestion schemes and reward programmes, and was the first to recognise that giving workers regular breaks improved their efficiency. The ultimate goal of his relentless pursuit of efficiency was, after all, that both employers and employees would be able to share in the rewards. Not all of Taylor’s ideas are right for us now, particularly his crude generalisations about the character of the working man (he did, after all, start out as an unskilled labourer in a steel works himself), but without his clear analysis of working processes, our more enlightened attitudes would scarcely be possible.