||

||

A building with straw-covered walls might sound like something from the tale of the three little pigs, but The Enterprise Centre at the University of East Anglia is, in fact, one of the UK’s most advanced and sustainable commercial buildings, and no amount of huffing and puffing is going to blow it down.

The thatch helps contribute to thermal efficiency, as well as giving a distinctive lookThe centre has a projected lifespan of 100 years and serves as a paragon of low embodied carbon construction. It forms a gateway to the university’s campus on the outskirts of Norwich and houses the headquarters of the Adapt Low Carbon Group, which provides a range of amenities to support low-carbon businesses. Its 3,400sq m floor space accommodates hatcheries and incubator units for SMEs and start-ups operating in the low-carbon sector, as well as an innovation lab, a 300-seat lecture theatre and flexible teaching facilities and workspaces. Morgan Sindall acted as main contractor, with a design team consisting of Passivhaus specialists Architype, structural and building services engineers BDP and Churchman Landscape Architects.

The thatch helps contribute to thermal efficiency, as well as giving a distinctive lookThe centre has a projected lifespan of 100 years and serves as a paragon of low embodied carbon construction. It forms a gateway to the university’s campus on the outskirts of Norwich and houses the headquarters of the Adapt Low Carbon Group, which provides a range of amenities to support low-carbon businesses. Its 3,400sq m floor space accommodates hatcheries and incubator units for SMEs and start-ups operating in the low-carbon sector, as well as an innovation lab, a 300-seat lecture theatre and flexible teaching facilities and workspaces. Morgan Sindall acted as main contractor, with a design team consisting of Passivhaus specialists Architype, structural and building services engineers BDP and Churchman Landscape Architects.

The centre’s prominent location on the campus, alongside Adapt’s very specific focus on promoting low-carbon initiatives, informed a brief that called for a showpiece of sustainable construction, which is among the first buildings in the country to target both BREEAM Outstanding and Passivhaus accreditation. For the architects, the need to keep embodied carbon to a minimum sparked a quest to identify suitable materials, particularly from local sources, that could fulfil the required aesthetic and functional criteria.

During this process, they identified the versatile properties of thatch and began looking into possible applications. They settled on using it to create a bristling layer of rainscreen cladding on the facades. “It’s an exemplary low-carbon building and we were keen that it should demonstrate that in a contemporary way,” says Architype’s director Ben Humphries. “In terms of impact and architecture, rainscreen cladding is often the first thing you see.”

Local timber creates the building’s underlying structureAs well as giving the building its distinctly organic appearance, the thatch contributes to its thermal efficiency, although it is technically separate from the thermal envelope. Architype and Morgan Sindall worked alongside local thatchers to develop a novel construction technique: prefabricated thatched cassettes were produced off site, which were later fixed to the framework using split battens.

Local timber creates the building’s underlying structureAs well as giving the building its distinctly organic appearance, the thatch contributes to its thermal efficiency, although it is technically separate from the thermal envelope. Architype and Morgan Sindall worked alongside local thatchers to develop a novel construction technique: prefabricated thatched cassettes were produced off site, which were later fixed to the framework using split battens.

This method saves time and hassle as the thatching can be conducted in any weather and without the need to balance on a ladder. The local thatching community helped to refine the idea, which Humphries says has never been done before. “None of us is aware of prefabricated thatch cassettes, so that’s an innovation we developed and implemented as a team,” he proudly claims.

A spray-on cellulose product made from recycled paper acts as an acoustic dampener

A spray-on cellulose product made from recycled paper acts as an acoustic dampener

Triple glazing helps to meet the building’s Passivhaus ambitionsThe use of thatch helps The Enterprise Centre complement its setting on the edge of the city’s Earlham Park, while glazing interspersed along the facades reflects the nearby trees. Due to its location beside the Grade II*-listed Earlham Hall and next to a peaceful memorial garden, both the local planning authority and English Heritage took a keen interest in the building’s development. Initial concerns that a contemporary intervention could conflict with these sensitive surroundings were eased by enthusiasm for the contemporary applications of vernacular materials, including the thatch and local flint used throughout the landscaping.

Triple glazing helps to meet the building’s Passivhaus ambitionsThe use of thatch helps The Enterprise Centre complement its setting on the edge of the city’s Earlham Park, while glazing interspersed along the facades reflects the nearby trees. Due to its location beside the Grade II*-listed Earlham Hall and next to a peaceful memorial garden, both the local planning authority and English Heritage took a keen interest in the building’s development. Initial concerns that a contemporary intervention could conflict with these sensitive surroundings were eased by enthusiasm for the contemporary applications of vernacular materials, including the thatch and local flint used throughout the landscaping.

“We always talked about creating ‘Norfolk in a building’,” says Humphries, adding that a taxi driver had recently commented on how the design seemed to capture the essence of the county.”

In addition to the straw thatch, a long list of low-impact materials has been applied in innovative ways throughout the building. An acetylated wood product called Medite Tricoya is used as an additional rainscreen cladding, while the roof is covered with traditional reed thatch. Internally, a spray-on cellulose material made from recycled paper provides acoustic dampening and the lobby features a polished concrete floor slab with a high content of ground granulated blast-furnace slag (GGBS), a by-product of the iron and steel industries. Other ways in which the building meets its environmental targets include the use of clay plaster, lime render, reed boards and fabrics made from nettles and hemp.

The curvy reception desk was repurposed from the Sainsbury Centre for Visual Arts

The curvy reception desk was repurposed from the Sainsbury Centre for Visual Arts

The initial proposal was even more ambitious but some ideas were discarded to reduce costs, while opportunism resulted in some unexpected materials finding their way into the scheme. The team was able to procure iroko timber originally used for desks in the university’s Denys Lasdun-designed chemistry building, which was repurposed as external cladding. “It was a real coup as we would never specify an African hardwood,” says Humphries. A curving metal reception desk designed by Foster + Partners for the nearby Sainsbury Centre for Visual Arts, but not used in its eventual refurbishment, now welcomes visitors.

The initial proposal was even more ambitious but some ideas were discarded to reduce costs, while opportunism resulted in some unexpected materials finding their way into the scheme. The team was able to procure iroko timber originally used for desks in the university’s Denys Lasdun-designed chemistry building, which was repurposed as external cladding. “It was a real coup as we would never specify an African hardwood,” says Humphries. A curving metal reception desk designed by Foster + Partners for the nearby Sainsbury Centre for Visual Arts, but not used in its eventual refurbishment, now welcomes visitors.

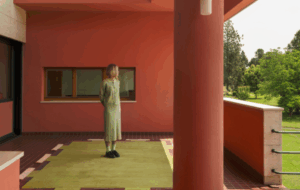

A window void links the office and boardroom spacesThe reception is located in a double-height exhibition and demonstration area at the rear of a central courtyard, into which the rendered volume of the lecture halls extends. On the opposite side of the courtyard, a canopy supported by columns of laminated larch from nearby Thetford Forest provides a sheltered transition between The Enterprise Centre and the rest of the campus. The exhibition area functions as a versatile social workspace that stretches along the full length of the building and unites the two wings at either end. Dramatic changes in height and plenty of glazing give it a spacious feel, while pods projecting from the first floor are clad in a range of materials that promote the centre’s ecological credentials.

A window void links the office and boardroom spacesThe reception is located in a double-height exhibition and demonstration area at the rear of a central courtyard, into which the rendered volume of the lecture halls extends. On the opposite side of the courtyard, a canopy supported by columns of laminated larch from nearby Thetford Forest provides a sheltered transition between The Enterprise Centre and the rest of the campus. The exhibition area functions as a versatile social workspace that stretches along the full length of the building and unites the two wings at either end. Dramatic changes in height and plenty of glazing give it a spacious feel, while pods projecting from the first floor are clad in a range of materials that promote the centre’s ecological credentials.

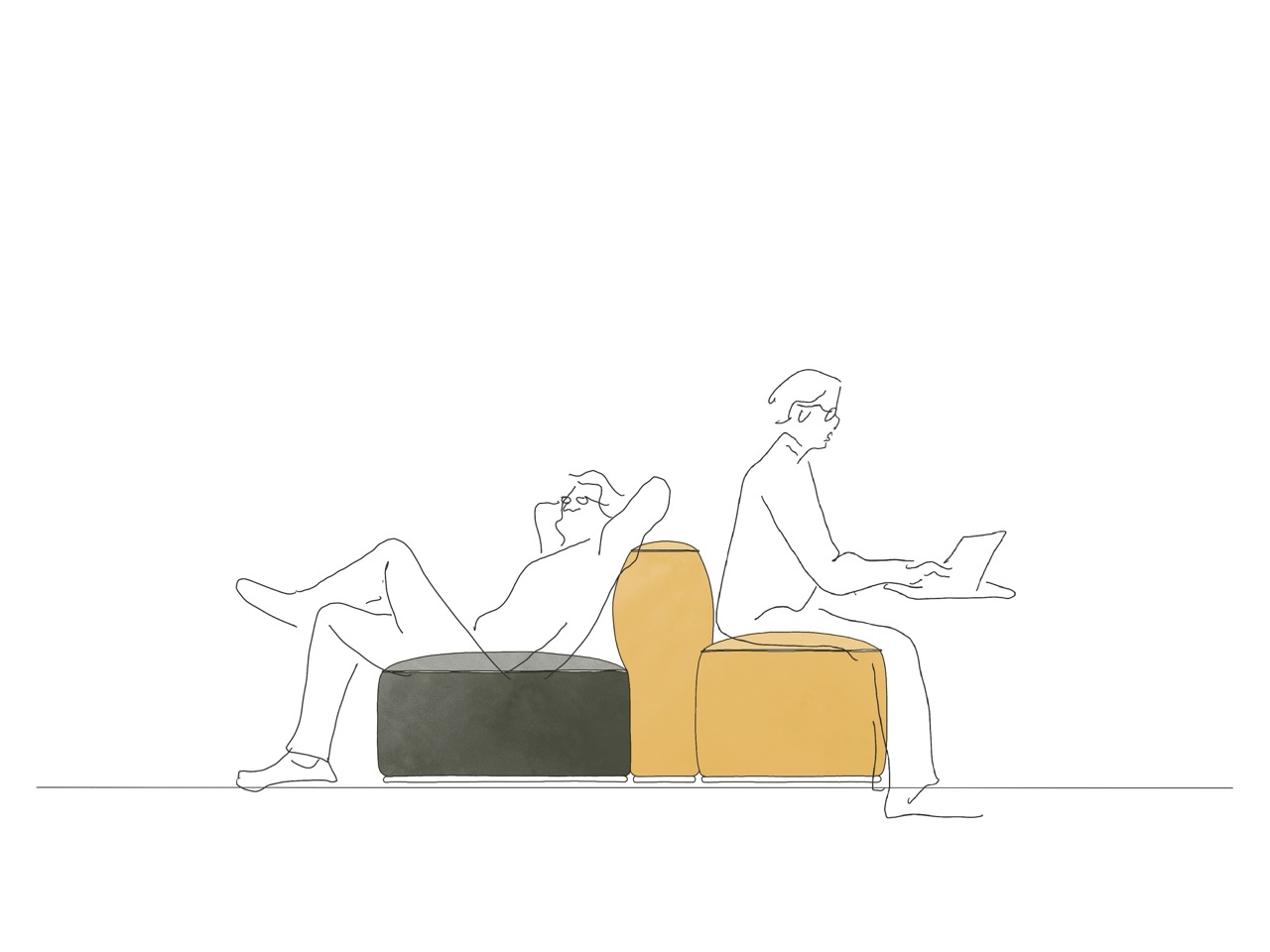

As with most modern educational facilities, the building offers a range of working environments that can be adapted to different uses, as well as breakout areas and dedicated teaching spaces. The ground floor contains a variety of seminar and lecture spaces, alongside rooms accommodating student enterprises and a hatchery where small businesses can hire desks. A larger hatchery on the first floor is predominantly dedicated to fixed workstations with some hotdesking opportunities. The rest of the rooms are adaptable teaching spaces, while the pods suspended above the exhibition hall contain a boardroom, a bar and a lab.

Architype has rented a desk in the first-floor hatchery so it can keep an eye on the centre’s use and evolution as part of a three-year post-occupancy and building performance evaluation programme, in collaboration with Morgan Sindall and the project team. This will enable it to provide the occupants with guidance to ensure the building continues to meet energy targets.

“What architects don’t do enough of is follow up on how their buildings are performing,” says Humphries. “Once we’ve been through three years and everything functions as designed, then I’ll be satisfied that we’ve done a good job.”

It has been four years since Architype’s first involvement in a project that involved dozens of stakeholders and demanded a deep dedication to fulfilling the most stringent environmental standards. The result is a world-class example of sustainable workplace architecture that demonstrates the capabilities of low-carbon materials. Not least among these is the straw, which Humphries says he hopes to use again in future projects.

“It’s a wonderful material and I’ve learned so much about it, working on this building,” he says. “I’ve seen a few other thatch-clad projects pop up since we started this, so you never know, it might just catch on.”

The low-carbon, straw-clad Enterprise Centre at the University of East Anglia – “Norfolk in a building” according to its architect – nurtures green businesses